The antimicrobial coating market is driven by the modern takes that tackle the spread of microbes on a surface. This approach goes beyond repeated cleaning of surfaces and emphasizes improving the resistance of surfaces against infection-causing pathogens. Antimicrobial coatings are an effective and safe way to deal with microbes and promote a high level of sanitization. The application of chemicals to protect the surface from the growth of disease-causing agents or microbes is the key motive behind the use of antimicrobial coatings. While there are plenty of other anti-corrosion options available in the market, antimicrobial coatings experienced traction of demand due to their effectiveness against bacteria, mildew, and molds.

Microbes growing on the painted surface can cause stains and deteriorate the paint film eventually. This reduces the integrity of paints. Coatings containing antimicrobial properties tend to inhibit the microbe’s growth and protect the film from degradation.

Antimicrobial coating technologies are not considerably new, they have been underutilization across some industries including marine, textiles, and medical devices so far. The traction of attention around sustainability has encouraged research and development in the antimicrobial coatings market. As sustainability likely to remain to be a top priority for paint companies, reducing the VOC content and toxic additions will be focused on by antimicrobial coating market participants.

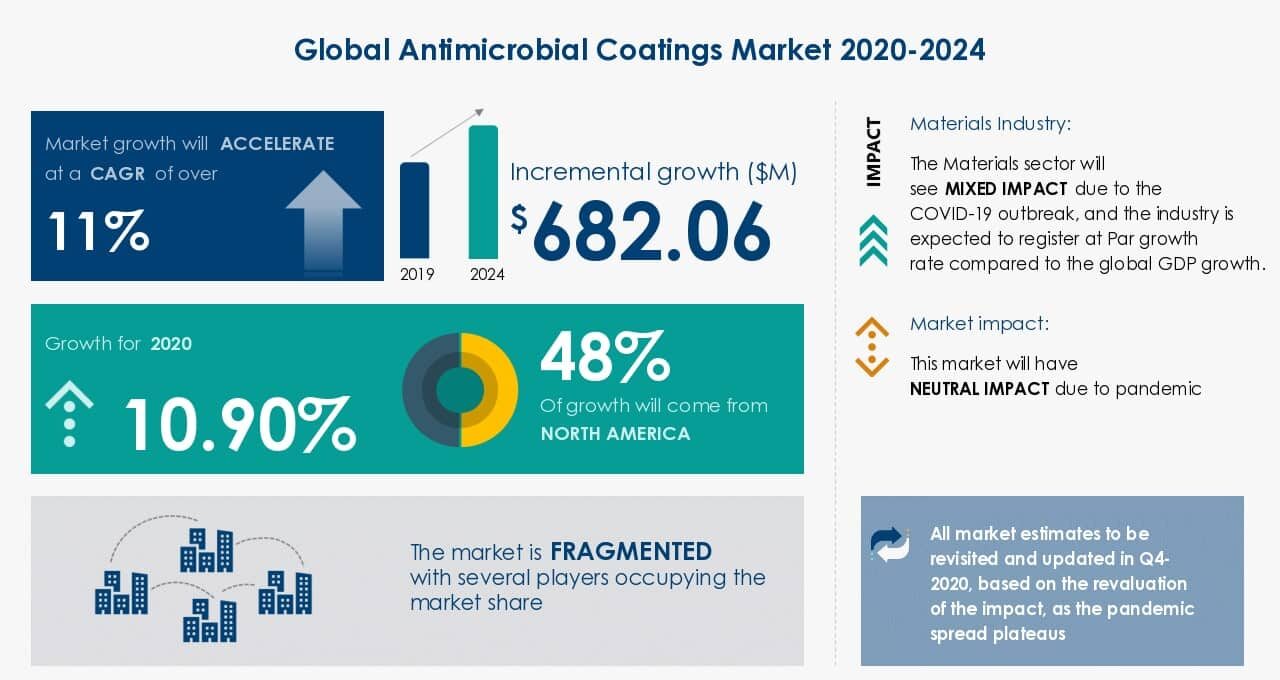

Insight Partners estimates the antimicrobial coating market to cross a valuation of USD 7,514.56 million by the end of 2028 from USD 2,918.30 million in 2019. This market is anticipated to grow with a CAGR of 11.2% in 2020- 2028.

Growing Green Chemistry – An Incentive for Bio-based Coating Market

As bio-based coatings cover a broad category of applications it is anticipated to retain high demand in the coming decade. These coatings are sustainable due to the use of natural resources in their formation. Majorly essential oils, foods, and forest products are used to make bio-based coatings. Bio-based coatings are preferred over conventional options due to their cost-effectiveness.

Recently in 2022, Boston Consulting Group has revealed that about 69% of companies are focused on their environmental commitments. These companies are opting for automation, AI, and data analytics to make operations efficient and reduce resource use. Global business policymakers are foreseen to emphasize on inclusion of eco-friendly practices and are likely to opt for bio-based coatings that align with their sustainability goals. These developments have favored the growth of the bio-based coating market in recent years.

Bio-based coatings market will gather lucrative revenue only when more manufacturers realize its usability and decide to switch and try them. Ongoing product releases in the bio-based coatings domain are foreseen to influence consumers’ purchases. Vegetable-derived solvents are emerging as 100% bio-based alternatives to petroleum-based variants.

The big driver of demand for the bio-based coating market is that people seeking products that impose less harm to the climate as well as themselves. Be it a DIY project or a particular job, consumers consistently look for fewer toxic components than their conventional counterparts.

Regulatory Factors Pushing Antimicrobial Coating Market R&D

Apart from heightened consumer awareness of harmful solvents and coating solutions, regulatory measures have encouraged manufacturers to invest in the antimicrobial coatings market. The Environmental Protection Agency in the USA has limited use of solvent content in coatings. Responding to this, antimicrobial coating market manufacturers have responded by transforming their paint and coating production. They have switched to water-based solvents and looking consistently for effective alternatives. More investment in products that are less toxic and more durable is foreseen to bring new options to the shelves in the coming year.

Another significant push is given by the European Union through project ReSolute which aims to produce safer paints by use of cellulosic feedstocks. This project is foreseen to achieve about a 20-fold increase in paint and coating production levels.

Trends in Antimicrobial Coating Market – Unlocking Revenue Streams for Manufacturers

Antimicrobial Coating for Medical Devices

Biocontamination of medical devices and implants is a growing issue revolving around the healthcare sector increasing complications and expenses. To fight against biocontamination, nanotechnology is being used to produce functional antimicrobial coating materials.

The growing significance of healthcare-associated infections has brought the cusp of investment in antimicrobial coatings for the medical devices market. The introduction of antimicrobial touch surfaces in hospitals is backed by the intent of preventing the threat of hospital-borne infections. Medical devices painted with antimicrobial coatings support existing hygiene standards and are also seen as effective in tackling the risk of antimicrobial resistance. Antimicrobial coatings made up of silver and copper are anticipated to curb healthcare-associated infections (HAIs).

“The antimicrobial coatings for medical device market are anticipated to cross a valuation of USD 3,851.96 million by the end of 2028, from a market valuation of USD 1,594.50 million in 2021. This market is projected to grow with a CAGR of 13.5% in the forecast period of 2022-2028.”

– The Insight Partners

Inorganic Antimicrobial Coatings for Neutralising Germs

Inorganic antimicrobial coatings have garnered significant demand in recent years due to their germ-neutralizing ability. These consist of layers of inorganic compounds aimed to curb the microbe’s reproduction ability. Silver and copper inorganic antimicrobial coatings are most commonly used. A combination of silver and copper works wonderfully surfaced to neutralize germs. Silver can destroy germs and interrupt their DNA replication.

The property of copper to trigger oxidative stress among germs is believed to make an excellent material for inorganic antimicrobial coats. Eventually, cells break down by oxidation leading to the protection of surfaces. In the healthcare domain, inorganic antimicrobial coatings are foreseen to gain upward traction in the coming year driven by transmission in healthcare practices and hygiene protocols.

Anti-fungal and anti-bacterial paints to safeguard Homes

Painting indeed adds magnificent difference to how a space looks, but today paints have evolved besides offering good looks to walls. They are now supposed to take care of other functional things to protect the wall against antifungal and antibacterial activities. An emulsified shield of antifungal paints can offer a smooth texture to the wall and protect it for a longer period. These antifungal paints are easy to clean and offer complete protection against germs. Growing emphasis on sustainable construction is anticipated to create lucrative space for the antimicrobial paints market driven by greater demand for durable and effective walls in commercial or residential segments.

Coating a wall with these paints will offer complete protection against moulds and make the wall resistant and durable. Improving air quality is a major area focused on by construction sector professionals while designing and choosing materials for buildings. There is increasingly observed alteration towards paints that promote a healthy environment inside the house. This is leading to growth in the low-VOC antimicrobial coating market.

Recent from the Coating Community-

- June 2021- Acer introduced an antimicrobial laptop which is coated with an antimicrobial agent covering the keyboard, frame, and fingerprint readers. Acer has pioneered the antimicrobial electronics trend which further extended to antimicrobial screen protectors.

- May 2023- Scientists have developed the metallic coating material for clothes and wearable textiles. The breathable electronic textile innovation is based on the principle of autonomously healing paints. These evenly coated textiles act as circuit interconnects compress the textile and improve electrical conductivity.

- June 2023- Antimicrobial Chitosan Coating to increase the shelf life of avocados. It delays the ripening of avocados by improving their shelf life.

- August 2023- Antimicrobial steel developed by Tata Steel has proven effective against bacteria when combined with paints. These products are foreseen to gain lucrative revenue in the antimicrobial coating market in the coming years due to their antimicrobial properties. The company has already exported 900 tons of coated steel and looking to patent this formulation shortly.

Market Players to Support the Collaboration for Manufacturing Progress

Antimicrobial coating market players at the top prefer collaborations to create new variants of functional coatings. Recently University of York has collaborated with Circa Group of Chemicals to announce a team collaboration for the formation of eco-friendly solvents. This collaboration aims to cater to the demand for antimicrobial coatings besides just applications in coatings towards wide areas such as textile recycling, and pharmaceuticals.

Top players are exploring silver nanoparticles by direct deposition on the surface or by polymeric surface coatings. Silver slowly kills bacteria on the surface and acts as an antimicrobial agent for medical devices. The antimicrobial efficacy of silver has become a key strategy by companies to prevent infections related to medical devices. We expect more collaborations in paints and coatings in the coming years.

Regional Growth Mapping

North American antimicrobial coating market was valued at USD 1083.59 million in 2018. This region is anticipated to continue dominance driven by the presence of key market players and advanced technologies.

Asia Pacific follows North America with a total of 20% of the global antimicrobial coating market share. Upsurge in urbanization and industrial arsenal have fostered demand for sustainable coating solutions. India has been one of the leading markets for paints and coating in the region. China is also expected to grow with a lucrative CAGR in the coming decade. Growth is foreseen to be driven by major industries such as healthcare, food packaging and processing, and construction.

The Insight Partner’s (TIP) Verdict

The global epidemic of COVID-19 has added stimulus to technologies and research in the antimicrobial coatings market in response to contagion. The demand for antimicrobial coats for surfaces is foreseen to remain constant even after the pandemic. The majority of demand is expected from healthcare centers, public transport, schools, and commercial centers to reduce human exposure to infectious pathogens.

The Insight Partner further estimates that the North American antimicrobial coating market will remain dominant in terms of investment and research from manufacturers in the coming decade.

Considerable research is ongoing in nanomaterials, their chemical modifications are soon to unleash new possibilities in the prevention of survival of viruses on surfaces. The use of nanomaterials has shown effectiveness against the microorganisms so far, yet there is a lack of assurance on their antiviral effectivity. As there is no specific study that allows for precise understanding, a high level of variation is witnessed across new coatings and their functionalities.

Despite of existing lack of standardization, the ongoing R&D in the antimicrobial coating market should be considered as a good start. Copper, Zinc, Titanium, and Silver are foreseen to remain key materials in consideration. Antimicrobial coating market players are foreseen to unlock new revenue streams by investing in the aforementioned key materials and technologies to remain competitive in the coming decade.